English

English Spanish

Spanish

Injection Molding Overview

Injection Molding Services that Produce High-Quality Molds

A1’s injection molding services and tooling will provide your products with maximum quality and value. Our team of experts will work with you to build a premium mold that will last.

Types of Injection Molds

See below the types of injection molding services we provide our clients. When A1 builds a mold, we build it to last.

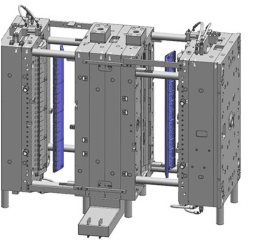

Stack Injection Molding

Without changing your molding press or tonnage, a stack mold increases productivity and reduces your part costs by using a stack of multiple mold layers (2 to 4). Simultaneously closing all layers in the stack enables molding all parts, in all layers, in one shot.

Tandem Molds

Also known as toggle molds or T molds, tandem molds alternately run one layer or the other. This plastic injection mold design allows for different parts and designs to be run in each layer, using different shot sizes or plastic volume in each half.

Multi-Shot Molds

A multi-shot (or two-shot) mold, combines two or more materials into one part in a single mold. When designed right, multi-shot molds significantly reduce the amount of scrap, cycle times, resin, work-in-process, and assembly; thus, driving down costs and improving the quality and consistency of the finished product.

Conventional Injection Molds

These molds are seldom “simple.” Simple or conventional molds are the most popular and where molding originated. Conventional molds may include multiple cavities, actions, materials (such as copper alloys), cooling methods, 3D-printed parts, or conformal cooling inserts; all engineered to improve the mold’s performance and part geometry.

Smart Molds

Smart molds are engineered to provide real-time meaningful information to improve molding efficiency. Data gathered is used to identify past trends, future predictable outcomes, and logs mold performance. Smart molds utilize predictive analytics, which can catch errors or maintenance issues before they occur, reducing costs and improving efficiency.

Thin Wall Plastic Injection Molds

Thin wall injection molds are specialized molds that focus on plastic parts that are thin and light. Expertise is needed to understand plastic shrink and tolerances. The thin wall parts provide product weight reduction, material cost savings, and faster cycle times; which means higher productivity and lower costs per part.

International (LCC/SET®)

Traditional LCC (Low-Cost Country) molds are typically inferior, cheap, unreliable and unsupported. A1’s proprietary Supported Economic Tooling (SET®) combines the superior quality and reliability of domestic tooling with the cost savings of international tooling. SET® molds are thoroughly vetted for design, function, quality, and supported by A1 Tool.

In-Mold Labeling (IML)

In-mold labeling (IML) is a process for decorating or labeling injection molded plastic parts or components during the plastic injection molding cycle. IML can be used on a wide variety of mold types.

Prototypes

Prototype molds are intended for testing part geometry, functionality, and low volume production. These molds are typically produced out of aluminum; however, they can also be made out of steel. A1 is in a unique position capable of producing prototype molds both domestically and internationally.

Custom Mold-Making Services

There are many, many more types of molds A1 produces on a regular basis, and we would love to discuss your unique molding needs. A1 does not produce blow molds and extrusion molds.

Sampling and Small Production Runs

Our sampling is done in-house, which means we offer your company the opportunity to improve your tool’s functionality and troubleshoot the process for higher mold throughput before it even leaves A1. We offer a variety of presses to sample molds and can provide sample parts for early testing to our customers on-site.

What is Injection Molding?

Injection molding is a manufacturing process used to produce parts in large quantities. It creates sample parts quickly and is cost-effective.

When to Use Injection Molding

If you need to produce an item in high volume, injection molding is ideal because it is repeatable. It will create consistently identical items. A1 delivers high-quality molds that are built to last. Learn more today.