INJECTION MOLD AND TOOLING

Specialty Tool Design and Engineering

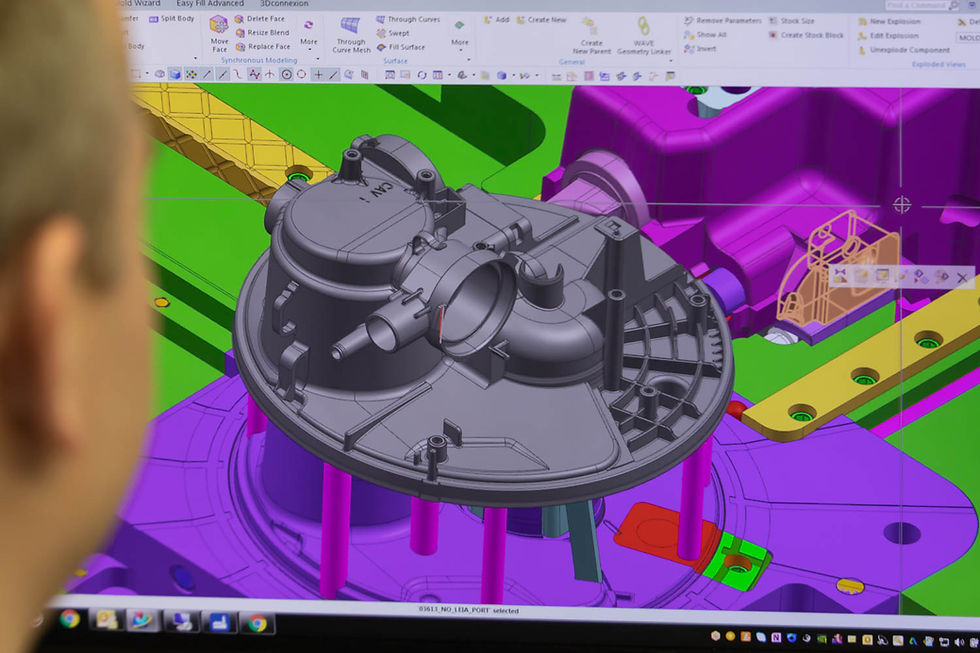

From pencils and drafting tables to CAD (Computer-Aided Design) and Moldflow Analysis, A1 has drastically changed from its 1946 roots. From those initial roots and through thousands of designs and highly trained, educated, and skilled designers come some of the most innovative engineering solutions. Our team of on-staff designers love a good challenge, where they can collectively find an economical and repeatable solution for your needs.

Consolidating multiple parts into a single mold, complex geometry, multi-action, multi-shot, or family stack molds, no challenge is too great.

Computer-Aided Design

Our engineering experts will collaborate with you to create dynamic solutions with the most robust design and functionality. We are creative thinkers who build tools to the highest standards with state-of-the-industry equipment. Our in-house design, manufacturing and mold sampling ensures accurate parts with the productivity and innovation you need.